>>> Click here to access this episode of the Syllab Podcast on Spotify <<<

a) Form and functions of automobiles

We saw in Chapter 1 on trains and pipelines the transformative impact the development of these modes of transport had on the economy and in particular its industrialization by reducing the cost of moving bulk and liquid cargoes even as the speed of doing so accelerated. The effect was also very significant when it came to the inner-city transport of people but much less outside of urban areas not served by a train line. Economics is only one of the reasons and there are other practical factors coming into play such as the lack of flexibility of scheduled public transport routes, whether it is the fixed routes or the fixed timing. Another important reason, which we alluded to in the previous chapter, has to do with topography because classic railroads are limited in the gradient locomotives can handle without slipping – this is the flip side of reduced friction of metal on metal versus rubber tires on roads – and rail-less roads also allow for overtaking and roadside stopping without having to wait for railway sidings.

Thus, when you combine a smaller steam engine with passenger seats, instead of having a separate steam locomotive and a passenger wagon, one gets the first automobile, which conceptually predated the locomotive in 1769 (invented by Cugnot, also the first person convicted of dangerous driving, or so the story goes), though it was not called thus and it had three wheels, a stable configuration with even roads and at slow speed. Automobiles, or the “car”, would go on to reshape the modern lifestyle post-WW2, providing baby-boomers with more freedom of movement than ever and triggering a massive migration of families towards the suburbs where larger land plots, cheaper houses and a better lifestyle awaited. Not coincidentally, this also marked the birth of the hypermarkets and large commercial centres at the periphery of large towns and cities. This is a strong argument to consider these and suburbs as an extended phenotype of car ownership – you may want to refer to S1 Section 3.c to better understand this notion.

I mention three wheels as a stable configuration under certain circumstances but this front-to-back asymmetry becomes a drawback at higher velocities and is prone to flipping if the centre of mass of the vehicle plus passengers is too elevated. Also, two wheels at the front provides better grip and ability to alter direction. Likewise, the position of the engine obeys physical considerations as well as safety ones in case of frontal impact in an accident. The combination of front-wheel drive and frontal engine might be propitious to understeering but this is easier to handle than oversteering. However, a mid-rear mounted engine allows for better weight distribution and cornering speed; it is thus favoured in race cars.

As for the seating arrangement, it has to optimize for both comfort and manoeuvrability with a driver at the front, potentially a passenger next to her in which case the two seats would be laid out symmetrically on either side of the longitudinal axis of the car. Since roads have limited width and to maintain adequate balance, the next seats are naturally positioned in a second row, and then possibly a third one. All of this crowd seats above the mechanical parts, because it is nicer to ride atop, easier to get in, and the heavier parts should be closest to the ground for improved stability. Thus, there is a reason why cars have similar shapes, even though they sport different curves.

b) The combustion engine and transmission

All right, that was form. Now, substance. How does a car move?

The basic principle is identical to that of the locomotive, it consists in converting one type of energy into mechanical energy and, thanks to a system of gears, develop torque to turn wheels and accelerate the vehicle and then maintain its cruising speed. This conversion occurs within an engine and in S5 Section 1.a we saw an example of chemical energy originating from the burning of fuel or coal being transformed into heat and the increased volume and kinetic energy applying pressure to a piston while in the subsequent S5 Section 1.b we looked into the electric engine and the use of a magnetic field to produce torque, leaving the petrol and diesel engines for us to understand in this section.

The petrol engine (also called gasoline engine in North America) and the diesel engine constitute two variations of internal combustion taking place within the engine itself, which differs from the external combustion of a fossil fuel seen with the steam engine, thereby eliminating one transformation stage. The ignition of the fuel triggers an explosion, a violent form of combustion, and it is the ensuing expansion of the high-pressure gas contained within the dedicated chamber that drives the movement of the pistons tightly slotted in the cylinders. Petrol contains a mixture of hydrocarbons (e.g. C8H18) and at high temperature and pressure it gets oxidized by oxygen molecules (O2) present within our atmosphere, yielding carbon dioxide (CO2) and water molecules (H2O) as products, releasing energy in the process. If you need to refresh your understanding of chemical reactions, you can do so by reading S1 Section 2.f and we also saw many examples of these throughout the Series 2 on the human body systems and senses.

In most cars and trucks, the generation of the ability to do work and harness it follows a 4-step process across two up-and-down cycles of the piston, hence the name of four-stroke engine. The first phase sees the opening of an intake valve sucking in air inside the chamber as the piston moves downward. On the way back up, it compresses the air to a high pressure and temperature before the power stroke takes place as the piston reaches the top. This is the 3rd phase of the cycle and the ignition can be created by a spark (from a spark plug receiving a brief high voltage), in which case fuel would have been mixed in with the air in phase #1, or fuel is injected at that moment and ignites under the effect of compression. This pushes the piston down with renewed impetus and, in the last phase, the combustion products are exhausted from the chamber. Fittingly, the spark version is called spark-ignition and the compression one is called compression-ignition.

When power-to-weight ratio is important, as on motorbikes, two-stroke engines may be preferred. Instead of a full cycle consisting of two revolutions of the crankshaft, everything happens within one revolution. The fuel ignition happens each time the piston is at the top but the exhaust of the combustion products and intake of air occur from the middle of the down phase to the middle (or so) of the up phase.

Diesel engines generally use compression-ignition and are preferred for use cases where higher torque is important, such as to operate utility vehicles and trucks. The primary reasons for that have to do with a slightly higher calorific value on a volumetric basis and a higher compression ratio in the cylinders. Nonetheless, they do not reach the same number of rpms so their horsepower tends to be lower than for petrol engines. Diesel is also a hydrocarbon but it is a heavier distillate compared to petrol and it tends to have more noxious sulphur, though this has been greatly reduced through regulation over several decades.

One last note before closing the matter of engines: higher-performance versions may also use a turbo system; the full name is actually “turbocharger”. It uses some of the exhaust energy to force more air inside the engine, this is called forced induction, which helps in producing more power. Because the turbo itself is powered by the engine exhaust, there is a noticeable lag in its operation until a certain revolution threshold has been reached – but it’s worth it as it allows smaller engines to compete with larger ones in terms of horsepower.

Moving on. The linear back-and-forth movement of the pistons creates a rotation of the crankshaft thanks to heavy-duty bearings and this rotational movement is carried over, via the gearbox, to the central shaft called axle connected to the wheelset with tractive power. As mentioned earlier, in non-performance-oriented cars this is generally the front wheelset. Not so with electric cars however because batteries can be placed more centrally compared to a combustion engine and having a rear-wheel drive provides better grip upon acceleration with this modified set-up.

When grip becomes a sought-after property, such as for off-road use, it is possible to power all wheels by having a transmission system which includes an intermediate gearbox so that both axles will provide torque to the wheels they are attached to. This four-wheel-drive mode can be always-on or engaged as and when required, and the gearing of the front and back axles can be decoupled thanks to the presence of the second gear box.

c) Control & Command

All this is certainly very impressive you may think, but it isn’t just about moving a car, it is about moving and controlling it at the same time. Well, the gearbox happens to be a central element in our ability to control a car. As anybody who has learned to drive a manual gearbox would know. For instance, lower gears provide more instantaneous acceleration and more engine brake while higher gears make a faster and less noisy ride possible – provided one has been going through each gears in turn. The gearbox (invented by a certain Mr Renault) is reminiscent of the cogs and wheels of a mechanical watch (refer to S4 Section 10.a) and, through the interaction of gears, it allows for the reduction or multiplication of torque as well as the changing of the direction of rotation from one shaft to another. The clutch pedal allows for the mechanical decoupling of the shaft attached to the engine and that driving the wheels, this provides the opportunity to engage another gear with a different revolution ratio between those two shafts. Automatic transmission works similarly at the conceptual level but differently in the details with, in most cases, a torque converter used instead of a friction clutch and the technology used for deciding the optimal shift points is nowadays driven by on-board computer algorithms. I include the link to the Wikipedia entry for automatic transmission for those who wish to dig deeper into this.

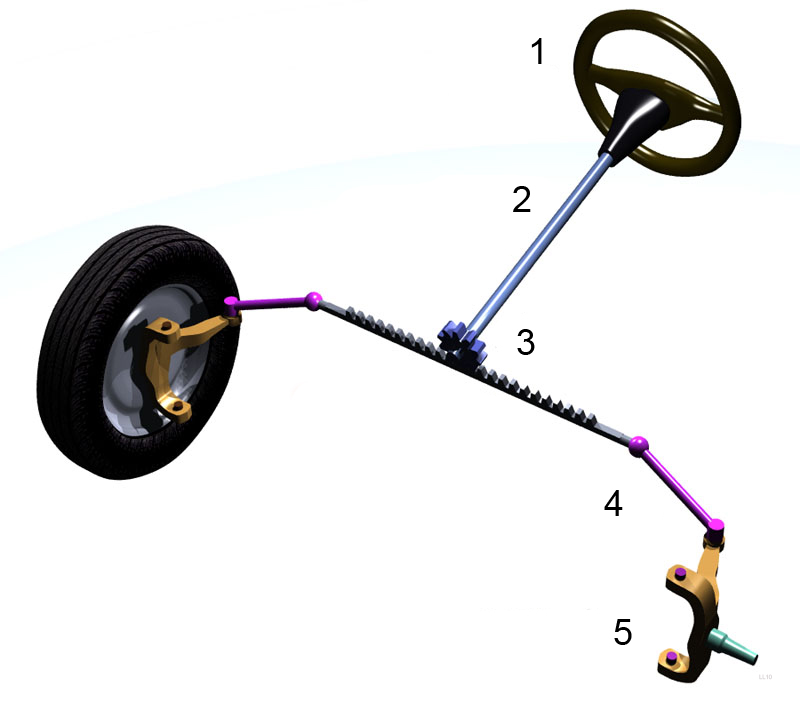

All things considered, perhaps the title of most obvious piece of controlling equipment goes to the steering wheel, that which enables us to turn left or right, including when reversing a car. The wheel piece is the user-interface component and the entire steering system consists of a column ending with a pinion actuating a transversal rack and this lateral motion is transmitted to the front wheels (and occasionally the rear wheelset as well) by a pair of steering arms and knuckles. I include a simplified visual rendition of a steering system as Figure 1 below. With heavy vehicles, the turning of the steering wheel can prove effortful, in particular at low speed and especially at rest, so most modern cars are set up with a power-assisted mechanism.

Figure 1: Steering system

Credit: by LaurensvanLieshout (CC BY-SA 3.0)

The steering wheel might be the most obvious piece of controlling equipment but directionality is only part of the velocity equation and regulating acceleration and deceleration provides the means to master the speed component. Acceleration is provided by the engine power and a key driver in how much power is produced is the volume of air or fuel that is allowed inside the combustion chamber. Less of it, less combustion, less power. The entry of the fluids is thus controlled mechanically by the pedal know as throttle or accelerator, which is suitably located immediately to the right of the braking pedal and designed to be operated by the same foot, which makes complete sense since a driver is not supposed to be braking and accelerating at the same time.

The objective of braking is to reduce speed and this entails transferring away some of the kinetic energy contained in the car in relation with the road frame of reference. The simplest way to do this is to create friction and thus dissipate energy via heat – just look at the incandescent disk brakes of Formula One cars before they take a sharp corner if you are not convinced, or just touch the point of contact between your bicycle brakes and the disk brake or the rim of your tires. When we press down on the brake pedal, this causes brake pads to press against drum brakes or disk brakes, however hybrid and fully electric cars attempt to recover most of the energy being shed rather than let it be dissipated. This is called regenerative breaking and works like an inverted electric motor where the mechanical rotation produces electrical energy that can be stored in batteries – we saw the principle of the electric motor in the previous chapter, in S5 Section 1.b on the electric locomotive.

For braking to be effective, the tires should remain in contact with the road and not skid, which can be caused by the road surface or by the blocking of the entire wheel. To address this issue, the anti-lock braking system (ABS) has been developed; it relies on wheel-speed sensors and an electronic control unit comparing this data with the speed of the vehicle to pre-empt any locking and reduce the braking force applied to each wheel as needed – and this can happen several times per second. Although this may lengthen the stopping distance, it allows the driver to retain greater control over the vehicle during the process and, for that matter, it is very effective in avoiding a total loss of control.

This mention of sensor provides a good segue to remind ourselves that control requires inputs that, after being mentally processed, inform the choice of action by the driver such as turning or decelerating. When driving a car, most of our inputs are visual in nature and have to do with the environment of the car, what happens on the road and roadside. In this sense, the rearview mirrors provides greater visual coverage, the light of our side indicators and our rear-brake lights provide information to other parties ahead or behind us, and headlights enable us to improve luminosity and therefore the quality of our perception. Nowadays, the predominant technology for headlamps is halogen and those who read S3 Section 3.f on the Antarctic Circumpolar Current may recognize the root word “hals” which refers to “salt” in ancient Greek. Halogen lamps are a type of incandescent lamp enclosed in a sealed and transparent volume together with a gaseous mixture of a halogen and an inert gas, the latter being one chemical substance that does not react easily. The main issue with the tungsten filament of traditional incandescent lamps is their short lifespan due to the evaporation of the material at high temperature, but the addition of a halogen such as bromine induces a reaction and precipitation of the metal back onto the filament. The more powerful high-intensity discharge lamp (HID) containing a noble gas such as xenon work by producing an electric arc; they are brighter, more energy efficient, and project light further down the road and to the sides, but they are also more expensive and the glare they produce can be blinding for incoming traffic or when seen through a rearview mirror by the driver of the car ahead.

Finally, a dashboard contains a few other indicators providing useful information based on various sensors such as the amount of fuel left in a tank or electricity in a battery, the engine temperature, the level of oil, the engine rpm, and of course the speed of the vehicle. All necessary for the ongoing safe operation of the vehicle – the equivalent of homeostasis for the human body.

d) What’s in a truck?

Just as there are passenger and freight trains, automobiles have a passenger and a freight version, the latter one being called truck (or lorry in some geographies). And just like freight wagons, these trucks come in all sizes with different qualities depending on the task they have been designed for. At the intersection of cars and trucks are utility vehicles, their primary distinction with passenger cars generally has to do more with the ability to transport larger payloads rather than more massive ones.

The heavier the payload, the stronger the chassis or frame as well as the suspensions, and the more tractive power is required, including more torque to tackle meaningful gradients and the initial challenge of getting the truck to move in the first place, when the rate of crankshaft revolution is low, without stalling – one of the primary reasons for using diesel rather than petrol engines. The wide adoption of containers to move non-bulk goods and commodities and the ability to dissociate the truck from the trailer enables a certain degree of standardization and versatility but otherwise many trucks are designed specifically for their job. Think fire trucks, mining trucks, refuse trucks, or concrete mixers.

Instead of the standard two-axle and four-wheel design, trucks commonly have three or more axles and tyres of varying size and rubber quality, sometimes with a diameter exceeding the height of a human being. Even the length can greatly vary and just as several wagons can be chained to form a train, some “road trains” can be formed by attaching several trailers to one prime mover. Don’t expect to see these in urban areas though, they tend to operate over sparsely populated zones with little gradient and you do not want to be on a bicycle when one of them goes past you.

Trucking operates in a complementary fashion with maritime transport but it competes against train and barge freight. From an economic standpoint, trucks are obviously more expensive to operate on an individual basis since they are more manpower-intensive, this despite compressing the rest time of truck drivers to barely-safe levels. Asphalt friction on rubber tires is also higher than metallic wheels on rails so the cost of fuel also ends up being higher. Nevertheless, trucks mostly follow point-to-point routes, thereby reducing the cost associated with double or triple handling, whether it is the use of classification yards or the loading of cargo from wagons to trucks for the “last mile” delivery. And of course, railroads are not present everywhere and trucks are less subject to waiting time until the next departure and are therefore the default option when speed of delivery is an important criteria in a commercial transaction. The comparison to barges is similar in many respects, those cannot traverse areas with significant gradients, they are slower, and they most likely involve multiple handlings unless the origin and destination are located along a canal or river.

All of this could undergo a dramatic change very soon though, on the back of the deployment of autonomous trucks that will slash costs associated with drivers once the fully-autonomous versions become operational. That said, what we can expect is not a strong pivot towards trucking but an optimization of freighting across all modes of transport, the real take-off of intermodal transport. But I am getting ahead of myself.

e) The autonomous paradigm shift

The degree of driving automation is categorized by the Society of Automobile Engineers (SAE) into 6 levels, from level zero with no machine input up to level 5 with no human driver. Level 1 and 2 have nice-to-have machine assistance, level 3 is the hybrid level where the identity of the driver depends on conditions and tasks, and level 4 is essentially autonomous but still requires a human driver to cater to specific circumstances. What I will be discussing here is level-5 autonomy, which is definitely coming once the broader population accepts the benefits and superiority of machines as drivers, and therefore the regulators agree to greenlight them.

Autonomous driving obeys the same principles and the same steps as human driving: the collection of inputs through sensors, their interpretation, and the running of algorithms producing outputs known as decisions, which trigger actions upon the various control elements of the vehicle we saw in sections a) and b). With human drivers, this involves our senses and our nervous system whereas for a machine the chain relies on hardware and software. Same, but different.

Hearing can provide sensory information, nonetheless the bulk of the input our brain processes pertains to the visual system and so it is unsurprising the progress in autonomous driving is tightly related to that of computer vision. This last task is a large and complex domain unto itself, which many people do not appreciate because they associate vision with the acquisition of information and we already have light-based sensor permitting us to detect and measure distances and features, thanks to technologies such as Lidar (I am enclosing the Wikipedia entry at the end of this chapter for those interested), with greater accuracy than the human eye. So, what is amiss?

To begin with, harvesting raw data and detecting features are not synonymous. The former does not automatically imply the latter. This is in fact a gross understatement and perception is altogether a different job, one which our brain performs in an impressive fashion thanks to the tens of millions of years of incremental improvements selected for among countless mutations by evolutionary pressure. This topic was previously broached in S2 Section 7.d on visual perception as well as more in depth in Chapter 3 of my book Higher Orders so I will not repeat the content here and only mention that the bottom-up process starting with edge detection must be complemented by a context-dependent top-down process seeking to associate the intermediate representation with established concepts such as a white dividing lines, another car or truck, stop signs and traffic lights, and more challengingly trying to make sense of the content within shadowed areas, of reflections, or to anticipate the behaviour of a pedestrian close to the roadside. This still lags compared to human performance but machines can draw on more capabilities, including direct vehicle-to-vehicle communication even when not in a line of sight. This is a key reason why the roll out of 5G networks with their lower data latency will drastically improve on-road safety: vehicles will be able to sense each other from a distance, day or night, whatever their speed, and coordinate their actions accordingly. This is part of the last aspect of the data processing, which is the decision-making and this obeys a set of algorithms, just like our brain.

This relates not merely to the ability to swerve, accelerate or brake but also to the optimizing of a journey based on traffic, state of the road, and re-routing if necessary. In the domain of freight, this superior ability to plan paths, when coupled with the absence of a human driver, is likely to lead to a dissociation between vehicle owners and operators and so trucks will not necessarily have to return to their point of departure after completing a delivery and we can expect rail freight to work increasingly as the trunk line of a pipeline with trucking ensuring the first and last mile deliveries.

Such efficiencies can also be expected in the business of passenger transport. The first impact we can anticipate is the wiping out of individual car ownership because it would be cheaper to have one show up at your door when you need it and not pay for an asset idling in a garage or parking lot. The pooling of passengers within a car may become a norm, algorithmically optimized depending on pick-up and drop-off location, and multi-car-pooling, like a road train, can drive energy and traffic efficiencies. Effectively, this would result in an extension of public transport capabilities, one with maximum flexibility and able to cover rural areas in an economically viable way.

Beyond these pragmatic considerations, autonomous driving would do away with human errors and therefore most road accidents so there is also an important emotional facet to the storyline and the whole passenger experience can be improved, in particular for the ex-driver who can dedicate this freed-up time to reading educational content such as Syllab or play cards with children – no need to be facing the road.

f) Trivia – the Bus

We talked about trucks and freight and forgot to cover the case where passengers are the cargo. This type of large people mover is called a bus or autobus and its capacity varies depending on size and structure, from the minibus dimensions to the double-decker or flexi-bus with essentially consists of a trailer coupled to the main structure.

The first bus service, or omnibus as it was called back then, occurred in the 1820s in France and was a horsedrawn carriage. Horsepower, literally. Then came the steam bus and the electric trolleybus. In its modern incarnations, it is based on combustion engines, electrical power, compressed natural gas or hydrogen fuel cells.

A bus can be used for charters, or repurposed as a large recreational vehicle, but the primary usage is as scheduled public transport and the sibling task of collecting and shuttling children and students between their residential areas and their education premises in the morning, and the other way around in the afternoon.

What, then, is the future of the bus in a world of fully autonomous vehicles? My guess is a lot more minibuses rather than larger configurations and a deeper penetration of this mode of transportation in suburban areas, including for office commuting.

g) Further reading (S5C2)

Suggested reads:

- Higher Orders, by Sylvain Labattu (buy)

- Wikipedia on Automatic transmission: https://en.wikipedia.org/wiki/Automatic_transmission

- Wikipedia on Lidar: https://en.wikipedia.org/wiki/Lidar

Previous Chapter: Trains & Pipelines

Next Chapter: Sailing Ships